This is where Helix typically evaluates a variety of Outline Specifications from various shipyards (which an Owner may be considering) and reports on the merits and disadvantages of the offers at hand. This process is followed by appraisal and comparison of a handful of the full Technical Specifications from the shipyards which the Owner has shortlisted. Finally a detailed analysis of the full Technical Specification of the chosen offer is made, resulting in a formal set of written technical comments, sent to the shipyard in order to ensure that the Owners requirements, in terms of both the vessel itself and the trade in which it would operate, are satisfied. This is normally followed by some back and forth correspondence on a technical level (and of course on a commercial level in parallel) resulting in an understanding between Owner and Builder.

Helix Shipping & Technical Services Ltd., London

HISTORY

Helix was established in London in 1966, as a marine consultancy and has been

continuously active in technical services to the shipping industry particularly in new build construction.

SINCE 2004

We have managed shipbuilding projects for:

| 87 |

DRY CARGO

(Handy size, Panamax, Supramax, Ultramax, Kamsarmax, Capesize) |

| 52 |

OIL TANKERS

(Oil product, Chemical, Coated LR2, Aframax, VLCC) |

| 27 |

GAS CARRIERS (VLGC)

|

| 7 |

CONTAINER SHIPS

|

| 4 |

SPECIAL OFFSHORE PSVs

|

United Kingdom, Netherlands, Denmark, Belgium, Germany, Poland, Rumania, Bulgaria, Croatia, Brazil, Japan, Korea, China and Philippines.

SERVICES

SERVICES

Helix usually attends the formal technical negotiations, held between the Owner and Builder, where the technical details are discussed and where finally the Technical Specification is amended to reflect the result agreed between the parties. In tandem the Shipbuilding Contract is usually negotiated by the commercial and legal team appointed by the Owner.

Helix undertakes the process of approval of the plans and drawings which are traditionally submitted by the Builder before commencement of construction at the shipyard. This process typically lasts for more than 1 year and necessitates regular correspondence with the shipyard, the classification society of the vessel and Owner's technical department.

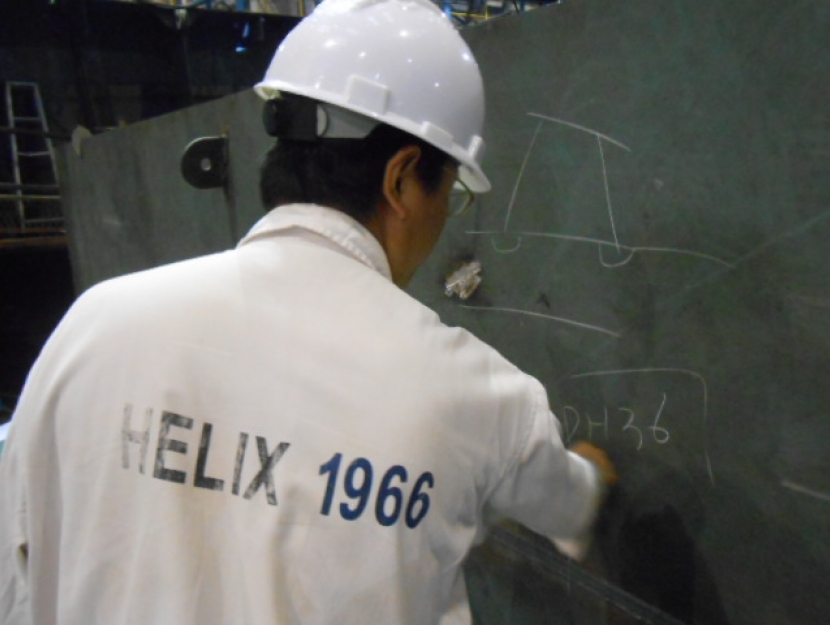

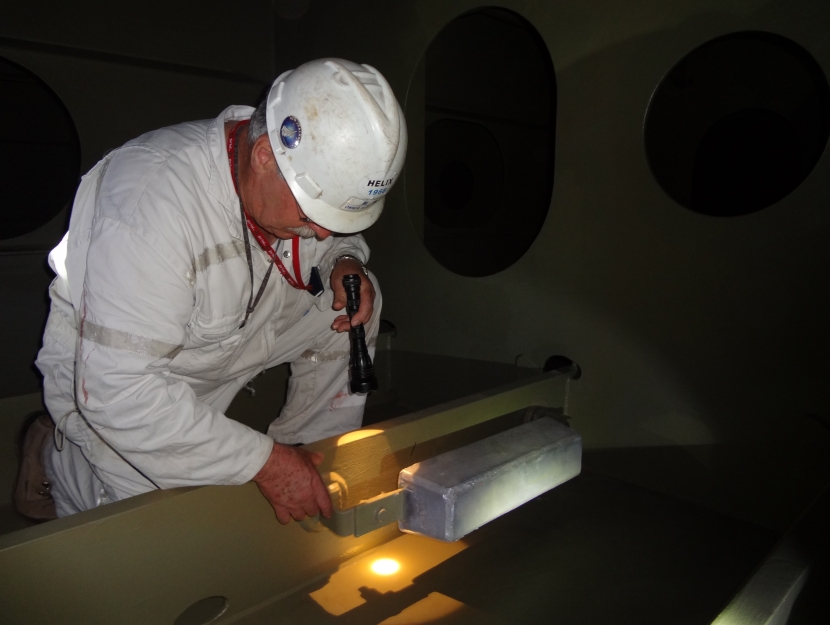

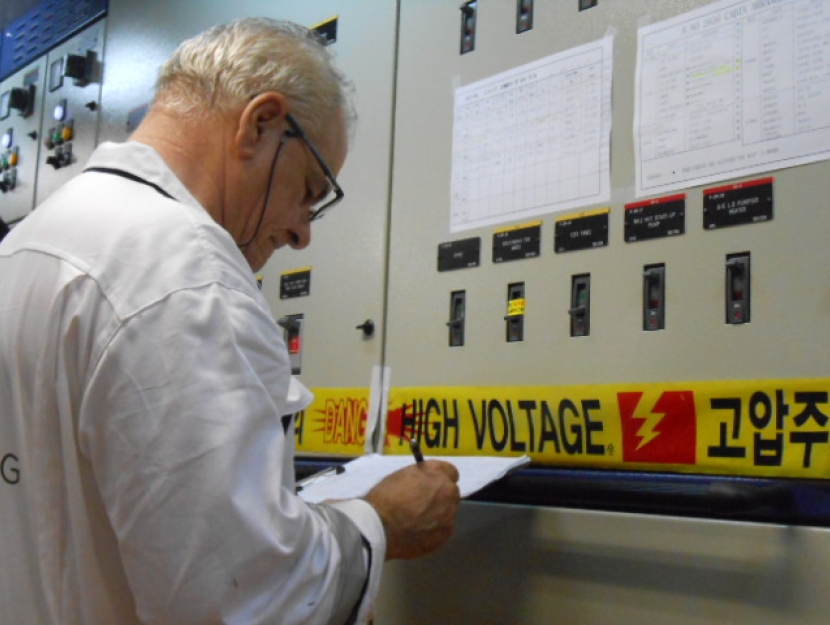

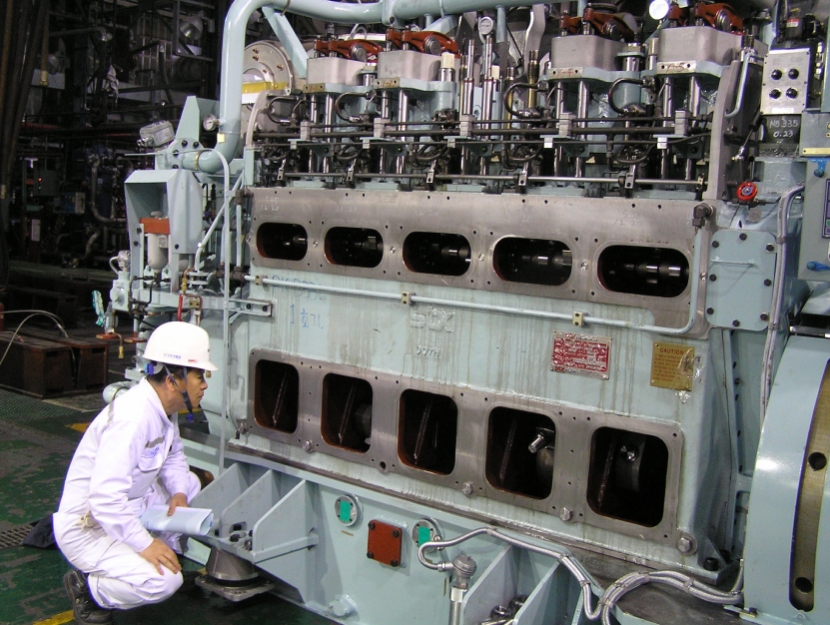

Helix undertakes the supervision of construction, as the Owners authorized representative in the shipyard and with responsibility for overseeing the progress of construction, its quality and the adherence to the rules & regulations, design & standards that have been agreed upon and which are set out in the Technical Specification and Shipbuilding Contract. This is achieved by both attendance during routine inspections arranged according to the shipyard’s production schedule and by patrolling at random in and around the shipyard. Additionally the Helix supervision team attend factory acceptance tests of important forgings, castings, equipment, etc which form part of the vessel in question. The supervision team is made up of inspectors, technically qualified in the disciplines of hull structure, paint and coatings, machinery etc.

PROJECTS

REFERENCE LIST SINCE 2004

| 4 | VLGC LPG | 80,000 m3 | HSHI-Korea | |

| 4 | VLGC LPG | 82,000 m3 | HHI-Korea | |

| 6 | VLGC LPG | 84,000 m3 | HHI-Korea | |

| 10 | VLGC LPG | 84,000 m3 | HSHI-Korea | * |

| 3 | VLGC LPG | 84,000 m3 | DSME-Korea | * |

| 10 | oil/chemical | 1,500~5,000 DWT | Miura-Japan | |

| 3 | oil/product | 3,500~4,500 DWT | Damen-Romania | |

| 3 | oil/chemical | 3,600 DWT | Nakatani-Japan | |

| 2 | oil/chemical | 6,100 DWT | Nakatani-Japan | |

| 4 | oil/chemical | 37,000 DWT | HMD-Korea | |

| 2 | MR | 46,000 DWT | STX-Korea | * |

| 2 | MR | 47,400 DWT | Uljanik-Croatia | |

| 1 | MR | 50,000 DWT | GSI-China | |

| 3 | MR | 50,500 DWT | GSI-China | |

| 1 | MR | 50,000 DWT | HMD-Korea | |

| 2 | MR | 50,000 DWT | DaeSun-Korea | |

| 2 | MR | 50,000 DWT | K-Shipbuilding - Korea | |

| 2 | MR | 52,000 DWT | HMD-Korea | |

| 3 | Panamax | 74,200 DWT | STX-Korea | |

| 2 | Aframax | 105,000 DWT | Sumitomo-Japan | |

| 3 | Aframax | 105,000 DWT | HHI.Offshore-Korea | |

| 2 | Aframax | 114,000 DWT | Hanjin-Philippines | |

| 3 | Aframax | 115,000 DWT | Sungdong-Korea | |

| 1 | Suezmax | 158,000 DWT | Sungdong-Korea | |

| 1 | VLCC | 300,000 DWT | HHSI-Korea |

| 2 | Handy | 34,200 DWT | Namura-Japan | |

| 1 | Handy | 37,000 DWT | Ouhua-China | |

| 1 | Handy | 37,000 DWT | HMD-Korea | |

| 2 | Supramax | 56,000 DWT | Bulyard-Bulgaria | |

| 3 | Supramax | 57,000 DWT | Cosco-Dalian-China | |

| 1 | Ultramax | 61,000 DWT | Imabari Tadotsu - Japan | |

| 1 | Ultramax | 62,000 DWT | Daesun-Korea | |

| 2 | Ultramax | 63,000 DWT | Imabari-Japan | |

| 1 | Ultramax | 63,500 DWT | Sinopacific-China | |

| 2 | Ultramax | 63,500 DWT | Sinopacific-China | |

| 2 | Ultramax | 64.000 DWT | New Dayang-China | |

| 4 | Panamax | 75,000 DWT | STX-Korea | |

| 2 | Panamax | 77,000 DWT | Sasebo-Japan | |

| 2 | Kamsarmax | 81,000 DWT | DACKS -China | |

| 2 | Kamsarmax | 81,000 DWT | SPP-Sacheon-Korea | |

| 3 | Kamsarmax | 81,000 DWT | Sungdong-Korea | |

| 2 | Kamsarmax | 81,000 DWT | STX-Korea | |

| 3 | Kamsarmax | 81,000 DWT | NACKS -China | |

| 2 | Kamsarmax | 81,000 DWT | NACKS -China | |

| 2 | Kamsarmax | 81,600 DWT | Tsuneishi-China | |

| 3 | Kamsarmax | 81,600 DWT | Tsuneishi-Japan | |

| 2 | Kamsarmax | 82,000 DWT | Ouhua-China | |

| 2 | Kamsarmax | 82,000 DWT | STX-Korea | |

| 3 | Kamsarmax | 82,000 DWT | Sungdong-Korea | |

| 2 | Kamsarmax | 82,000 DWT | HHI.Offshore-Korea | |

| 3 | Kamsarmax | 82,000 DWT | HHI-Korea | |

| 1 | Kamsarmax | 82,000 DWT | Hudong-China | |

| 5 | Kamsarmax | 82,000 DWT | Hudong-China | |

| 2 | Kamsarmax | 82,000 DWT | Jiangnan-China | |

| 6 | Kamsarmax | 82,000 DWT | Shanghai-China | |

| 2 | Kamsarmax | 82,000 DWT | Shanghai-China | * |

| 2 | Kamsarmax | 82,500 DWT | COSCO Yangzhou-China | |

| 2 | Kamsarmax | 84,000 DWT | Tsuneishi-Zhoushan | * |

| 1 | post-Panamax | 84,000 DWT | Sasebo-Japan | |

| 6 | post-Panamax | 87,000 DWT | Hudong-China | |

| 2 | Capesize | 175,000 DWT | HHI.Samho-Korea | |

| 2 | Capesize | 175,000 DWT | HHI.Samho-Korea | |

| 1 | Capesize | 175,000 DWT | Hanjin-Philippines | * |

| 4 | Feeder | 2,600 TEU | STX-Korea |

| 3 | Feeder | 2,600 TEU | STX-Korea |

| 4 | PSV | 52 tanks, 200 man | Yantai-Raffles-China |

OUR MANAGEMENT TEAM

BSc. Naval Architect

(Durham University)Fellow of the Society of Consulting Marine Engineers & Ship Surveyors

BSc. Mechanical Engineering

(Sunderland University)MSc Marine Technology

(Newcastle University)Member of the Technical Committee of Lloyd’s Register of Shipping

Helix Surveyors & Inspectors

CONTACT

RECRUIT

For employment opportunities as:

• Surveyors

• Naval Architects

• Marine Engineers

• Mechanical Engineers

• Inspectors (Hull, Coating, Machinery, Electrical)

Please submit your Resume or CV to elias@helix1966.com